Kurova & Kufa Kwekudzvanywa Kwemapiritsi

Zvinhu zvirimo

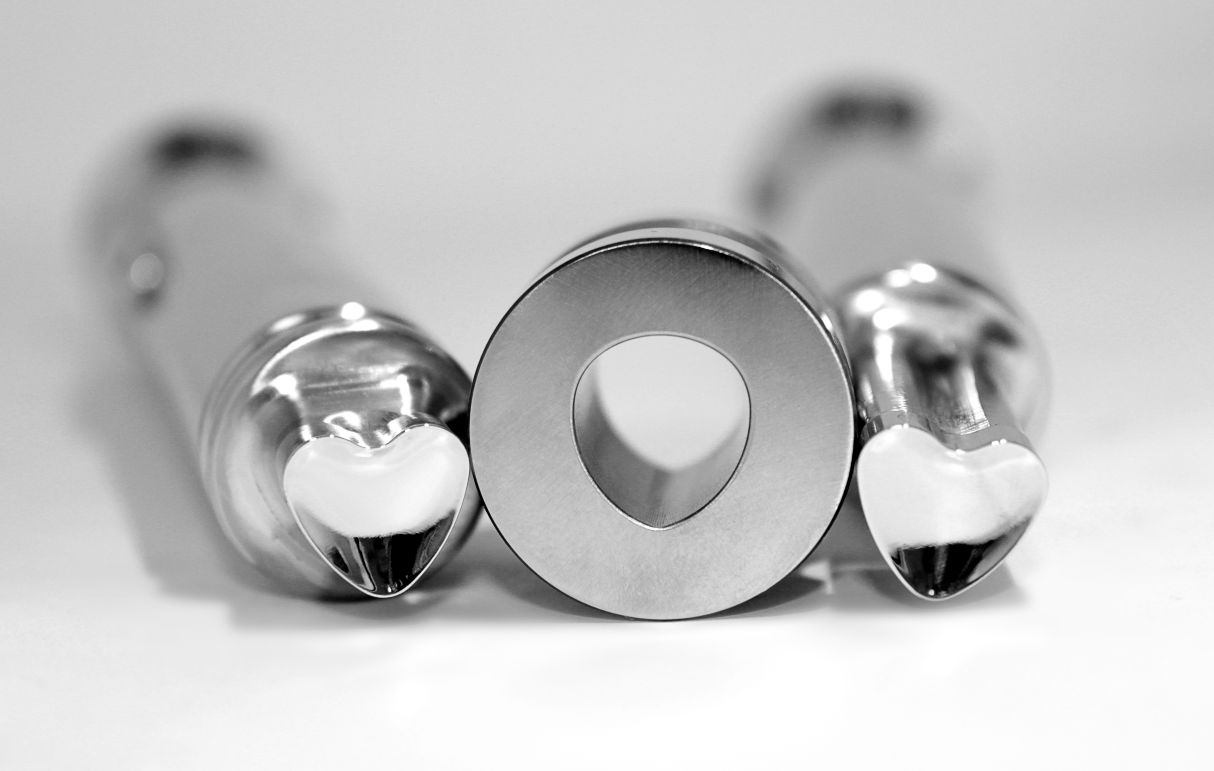

Sechikamu chakakosha chemuchina wekudzvanya mapiritsi, matableting Tooling anogadzirwa isu pachedu uye mhando yawo inodzorwa zvakanyanya. PaCNC CENTER, timu yehunyanzvi yekugadzira inogadzira nekungwarira uye inogadzira matableting Tooling ese.

Tine ruzivo rwakakura rwekugadzira mhando dzese dzezvibhakera nemadhiya akadai sedenderedzwa uye chimiro chakakosha, shallow concave, deep concave, bevel edged, de-tachable, single tipped, multi tipped uye ne hard chrome plating.

Hatisi kungogamuchira maodha chete, asi tiri kupawo mhinduro dzakazara dzekugadzirira kwakasimba kubatsira vatengi kuita sarudzo dzakakodzera.

Kuburikidza neongororo yakadzama yekutenga zvinhu pachine nguva nechikwata chine ruzivo rwebasa revatengi kudzivirira matambudziko. Nekudzora kwakasimba kwemaitiro ekugadzira uye mushumo wekuongorora wakazadziswa kuitira kuti maToolings ese agone kumira zvakanaka.

Zvichienderana nezvinodiwa nemutengi, hatingope chete ma punch nema dies akajairwa, akadai seEU neTSM, asiwo chishandiso chakakosha chetablet kuti tikwanise kuzadzisa zvinodiwa nemutengi. Zvinhu zvakasiyana-siyana zve punch nema dies pamwe ne coating, izvo zvinogona kugadziriswa chete nemakore eruzivo.

Kugadzira mapiritsi emhando yepamusoro. Zvishandiso zvemapiritsi zvinobvumira muchina wekudhinda mapiritsi kugadzira mhando dzakasiyana dzemapiritsi. Kugadzira mapiritsi akasiyana-siyana kunowedzera simba rekushandisa uye kunoderedza nguva yekugadzira.

Kugadzirisa

1. Kana kugadzirwa kwapera, kuongororwa kwakazara kweTooling kunodiwa;

2. Chenesa uye pukuta chiumbwa chose kuti uve nechokwadi chekuchena kweTooling;

3. Chenesa marara muTooling kuti uve nechokwadi chekuti hapana mafuta anorasika mubhokisi remarara;

4. Kana ikachengetwa kwenguva pfupi, ipfapfaidze nemafuta anodzivirira ngura mushure mekuichenesa woiisa mukabati reTooling;

5. Kana maTooling akashandiswa kwenguva yakareba, achenese woaisa mubhokisi remold rine dhiziri pasi.

Zvikamu zvezvigadzirwa

Tsamba Yedu Yevhiki Nevhiki

Ichokwadi chakagara chakasimbiswa kuti mudzikinuri achagutsikana ne

peji rinoverengwa kana uchitsvaga.

-

E-mail

-

Runhare

-

WhatsApp

-

Pamusoro